Philips Compact Disc Digital Audio represent an outstanding advance in audio technology. It enables standards of reproduction, previously unattainable through traditional recording, mastering, and replication methods, to become a reality. This has been made possible through the development of techniques and equipment which enable audio information to be converted into a digital format, and transferred by optical means onto a disc. To achieve this breakthrough, Philips has used what is possibly today's most advanced tool...the laser...both in the Compact Disc Player itself and also in the mastering process. In addition, our extensive experience in audio technology, plus Philips worldwide research and development facilities have been combined to realise our aim for the optimum in sound reproduction...

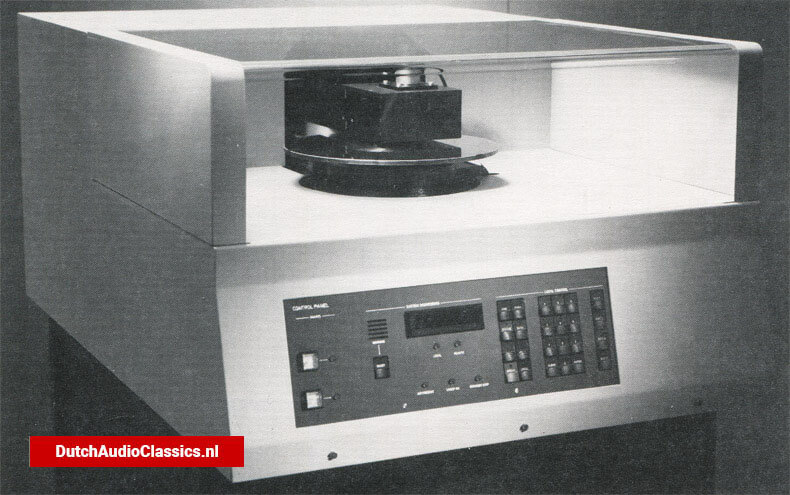

Compact Disc Universal Inspection Player

- Enables automatic, comprehensive quality control checking of Compact Disc Masters, Shells, Stampers, and Replicas

- Ideal for error propagation measurements, in successive steps in the Mastering, Matrixing, and Replication processes.

- Checks both the specified program area of the disc, and the test signal area (inner and outer bands)

- Verification capabilities include the HF-signal, symmetry, decoding errors, audio signal quality, subocde, radial tracking error, and focus error

- Choice of manual or remote control (IEC-625 controller)

The Philips LHH0426 Universal Inspection Players forms the main part of a test system that enables extensive measurements on Compact Disc Masters, Shells, Stampers, and Replicas. Measurements can be taken automatically, and measured data presented in a variety of formats.

Modular construction

The Universal Inspection Player comprises three basic modules:

- The opto-mechanical unit, which consists of the rotation motor, optical pick-up assembly, and the sledge, together with all related electronics. The unit is mounted on the upper part of the Universal Inspection Player on a base plate which is isolated against vibration

- The servo-unit. This contains the electronics for the rotation-servo, radial-servo, focus-servo, servo-control, and the interface (including an IEC-625 remote control bus).

- The decoder unit, which includes the basic decoder electronics and several slots for the installation of a variety of options.

Comprehensive capabilities

The audio signal quality of the Philips LHH0426 is determined by the properties of the decoder circuitry as, for example, errors on the disc could be masked by one decoder strategy and not by another.

The Universal Inspection Player gives the user the ability to verify the quality of Disc Masters, Shells, Stampers, and Replicas, using several different decoder strategies. The layout of the circuitry is such that changover from one decoder to another (different strategiy) is easily accomplished by exchanging a board in the decoder electronics unit.

The following decoders are available:

- Decoder based on a 7-frame strategy

- Decoder based on a 8-frame strategy, with oversampling DA-conversion (several adaptions make this ideal for error detection and counting)

- Decoder based on a 8-frame strategy

Available options include:

- Decoder controller interface with IEC-625 bus

- Subcode processing and interface

- Programmable error counting

- General purpose interface

- Analogue audio output

- Digital audio output

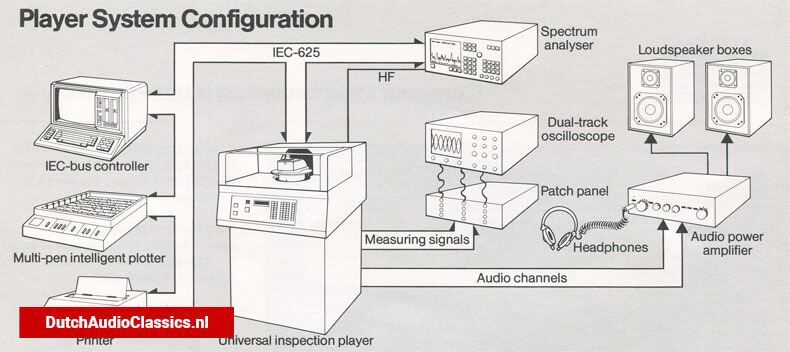

Player system configuration

A typical system configuration is illustrated. Here, the test program which is stored by the user in the memory of the IEC-bus controller, evolves fully automatically. Output of the measured data is possible in a variety of forms - as plots on the mutli-pen intelligent plotter; tables or forms on the printer; or volatile data on the screen of the controller. It is also possible to monitor specific analogue signals on a dual trace oscilloscope for evaluation of signal properties.

Technical data

Dimensions and weight

Height: 11175mm

Depth: 860mm

Width: 660mm

Weight: approx 350kg

Accessoires

User manual; power cord; set of fuses

Mains voltage

110/220V +/-10%, 60/60Hz +/-4% user selectable

Power consumption

300VA

Evironmental conditions

Operating under dust-free conditions (class 100)

Temperature:

- operating: +15C to +35C

- non-operating: -20C to +70C

Relative humidity: 30-70% noncondensing

Optics

Wavelength: 800mm +/-20nm

Numerical aperture: 0,45

Diffraction limited optics

Linear polarisation

Nominal power readout spot 87 micro watt

Safety class 1 - according to regulations U.S. -dept. HEW (FDA)

Servos

Focus:

Mechanical range +/-0,8mm

Max.focus error 0,1 micrometer

Bandwidth 800Hz

Reduction at 13Hz > 57dB

Radial tracking:

Mechanical range: 18-60mm

Max.tracking error 0,1 micrometer

Bandwidth 500Hz

Reduction at 13Hz > 57dB

Rotation:

Range 3 to 13Hz

Bandwidth 12Hz

HF Pre-amplifier

Bandwidth: 0-5MHz

Noise: -80dBm at 500kHz (b.w. 10kHz)

Headphone amplifier

Load impedance 600 ohms

Max.output level +10dBm

THD -100dB

SNR -100dB

Terminal overview

HF-out: Analogue

Diode segment A: Analogue

Diode segment B: Analogue

Focus error: Analogue

Radial error: Analogue

Laser current: Analogue

Radius output: Analogue

Tacho/2: TTL

Rotation pulse: TTL

Marker signal output: TTL

Decoders error (decoder dependable): TTL

HFD (70% of HF-level): TTL

DOD (30% of HF-level): TTL

Subcode output: To be specified

Error valid output: TTL

Headphone output: Analogue

Audio output channel 1: Analogue

Audio output channel 2: Analogue

HF-input: Analogue

HF-clockout: TTL

Ext. word clock: TTL

IEC-625 remote control: Logic

Brochure Philips LHH0426