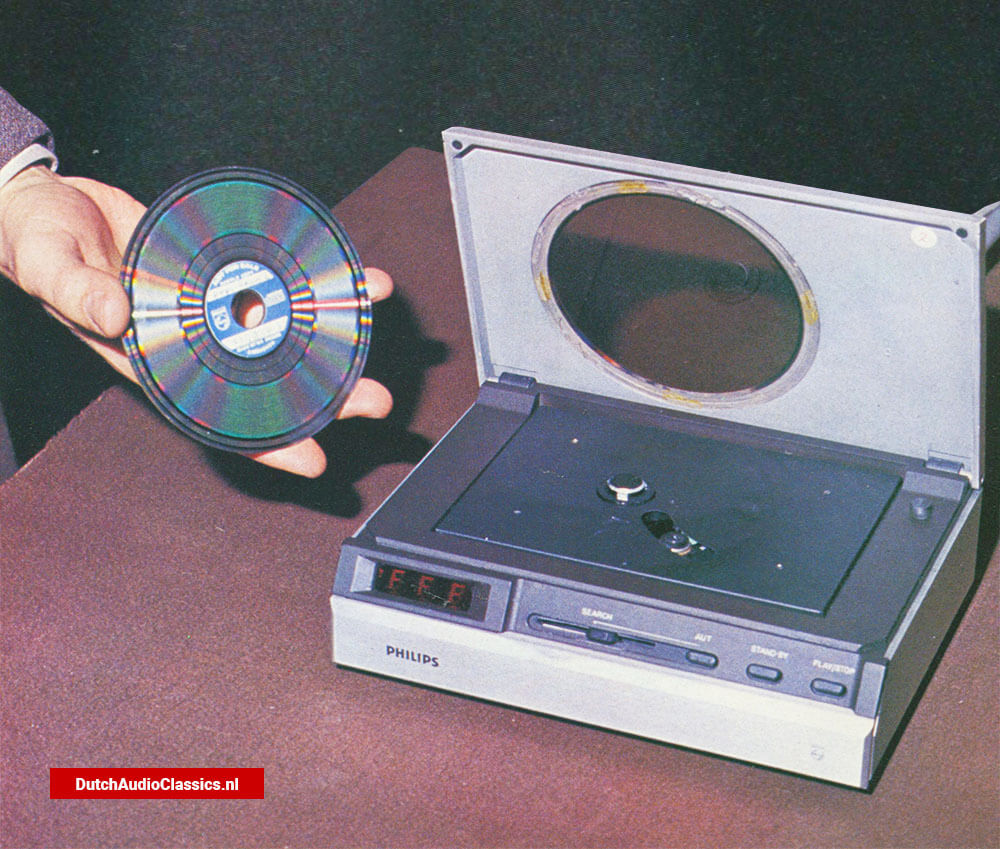

In May 1978, Philips announced that they were working on an audio PCM disc; at a seminar held at their headquarters in Eindhoven coincidentally with the Festival du Son, they introduced their 'Compact Disc' system to journalists and engineers. Unlike the Japanese, who have been working on a video/audio compatible system using a 30 cm disc and the same player for each function, Philips have gone for a separate audio system based on a onesided 11.5 cm disc which plays for one hour and which is totally incompatible with their VLP video disc, now on sale in America. Their reasons are mainly that by keeping the physical size small and designing an audio- only system, price for both disc and player will be competitive—they quoted prices, when asked, of around £5 and £150 respectively at today's prices. ( See contents page for pic of player and disc).

8 March 1979The introduction of the Philips Compact Disc System

General reaction to the sound quality amongst the hard-bitten press at the launch was one of almost unreserved appreciation; apart from a slight ' steeliness' which could well be attributed to the ancillary gear. At the heart of the system is a PVC disc encoded with a series of pits smaller then 1p,m long by 0.4 p.m wide. These pits, each of which ( or the lack of) indicates one ' bit', form a spiral track starting at the centre of the disc and ending at the edge, the opposite way round to a normal LP, and these pits are 'read' by a semiconductor laser, total length only 45 mm, focused very precisely. A photodiode picks up the reflected light and this is fed to a D/A ( Digital to Analogue) converter which recovers the original music signal and which can be fed to the auxiliary input of an amplifier.

There are a number of points of special interest to the system. Unlike the LP, which revolves with constant angular velocity (34 rpm), the Compact Disc revolves with constant linear velocity, varying from 500 rpm at the innermost track to 215 at the outer edge. A quartz oscillator controls motor speed, and the player is actually instructed what the velocity should be at any one moment by information coded on the disc itself. The information layer is covered with a transparent layer 11 mm thick through which the laser light passes, and because the light is focused onto the pits with a very short focal length lens, the light circle, 1.87 p.m in diameter on the pits, has expanded to 1 mm in diameter on the surface, so any dust particles will be well out of focus and only intercept a fraction of the light. The obvious result is a disc immune to noises induced by dust and handling—a great boon to all those who have given up hope of ever finding quiet records.

A prototype Compact Disc player with a 11.5cm Compact Disc

A prototype Compact Disc player with a 11.5cm Compact Disc

The effect of that other analogue disc bugbear, the warp, has also been minimised in the Compact Disc. The laser follows warps up to 1 mm in height ( which represents quite a sizeable warp on a record only 11.5 cm in diameter) keeping the pits in focus. The information on the disc is multiplexed, ie left and right channel information is mixed up in a regular order with the additional information ' words' ( containing the velocity, synchronisation, etc information) and there is no reason why, if the speed is doubled, twice as many information channels cannot be carried.

These are all advantages due to the mechanical processes used; what about the PCM side? The one basic advantage of PCM is that imperfections in the recording and reproduction medium are no longer of any consequence; all that is required is that the system be capable of distinguishing between two levels of signal only instead of the infinite number in an analogue system. This means that any duplication of a digitally encoded signal will not degrade it at all, and system faults such as wow and flutter are largely irrelevant. If a Compact Disc has been cut from a digitally recorded master tape, the sound you will hear in your living room will be an exact replica of that heard in the control room ( it doesn't do anything to correct poor production, so our Record Review section will still have a raison d'être). The only degradation suffered by the mike signals will be that imposed by the PCM process itself. The signal has to be severely bandpass limited— if signals up to 20 kHz are to be described accurately, a sampling frequency of > 40 kHz has to be used, but if any frequencies > 20 kHz are present they will then intermod with the sampling frequency, causing a particularly nasty audio degradation called ' aliasing'. A steep low pass filter has to be used and the design of this can present some problems. To a lesser extent, the signal can be affected by the A/D ( Analogue to Digital) conversion but degradation can be kept to a minimum by choosing the optimum number of bits in each digital word used to describe the state of the signal. To get the 20 kHz bandwidth, Philips use a sampling frequency of 44.3 kHz, ie, the amplitude of the signal is described 44,300 times every second and this amplitude is described as a 14 bit word. A 14 bit linear system enables the signal to be split into 2m-1 equal levels ( = 16,383) and as each bit contributes around 6 dB to theS/N ratio, the intrinsic S/N ratio of the 14 bit Philips system is 85 dB. This is, in fact, increased to around 92 dB with pre- and deemphasis, ( compared with 30 dB for a 78 or 60 dB for an LP). Crosstalk between channels is also correspondingly extremely low.

Disc production is analogous to LP production. The master disc is a glass plate with a photosensitive layer onto which a high power laser writes the information. This is then developed leaving a pattern of pits in the glass plate. A galvanic process produces stampers which are used to press records in the normal way and after pressing, an extremely thin reflective coating is deposited behind the pits and the disc is protected by a transparent coat.

The disc measures 11.5 centimeters in diameter and is only 1.1 millimeters thick

The disc measures 11.5 centimeters in diameter and is only 1.1 millimeters thick

The prototype works; the main question is when and if it will ever appear commercially. The two major problems are lack of standardisation, both on the mechanical and PCM parameters involved, and the reluctance of the record industry to embark on the very expensive process of introducing a complete new medium — there have only been four since Edison, the cylinder, 78 disc, LP disc and the cassette.

If the intended competitive pricing of the Compact Disc is viable, this could well prove the main advantage over the audio/video compatible systems. Quality at any price is always acceptable to a few but the same quality at a price the man in the street can afford will be a winner. Philips say that they intend to operate the same ' liberal' attitude to licensing hardware production by other manufacturers that was applied when they introduced the Compact Cassette in 1963 and it is pertinent to remember that this was a major factor in the rapid expansion of the cassette medium. Philips also have a 50% interest in Polygram, the company operating all the Philips record labels, and obviously the chance of Polygram adopting the Compact Disc format rather than a Japanese one must be high. One thing is certain, it will be the '80s before any system is released commercially and the analogue disc should at least survive until the next century. However, what will happen to all those firms whose whole success is based on producing one component of the analogue player? Presumably Ivor Tiefenbrun has a winning formula up his sleeve!