March 1982

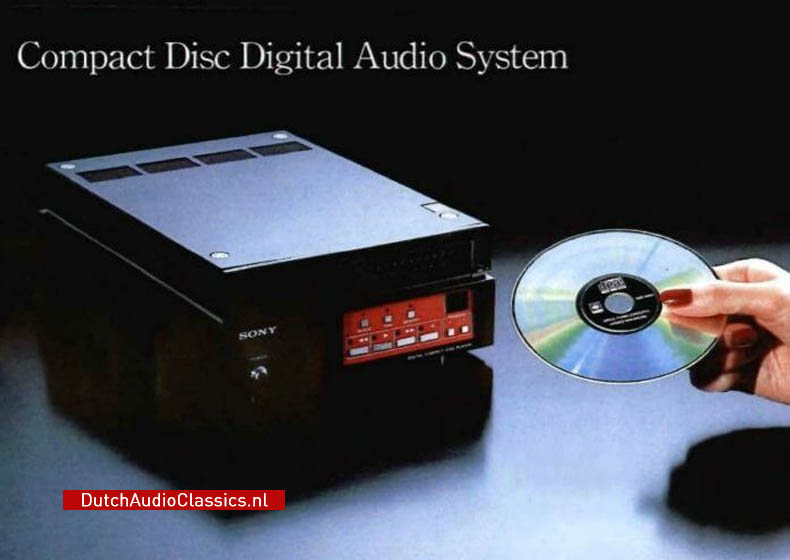

So far, digital -audio recording technology has confined itself to tape. Now, digital discs are about to make Their debut.

Major revolution

The spring of 1981 will probably go down in history as the time when a major revolution in the science of sound recording took place. During April and May of that year, Holland's Philips Company and Japan's Sony Corporation, in jointly held presentations in Europe and the United States, announced their plans for the introduction of what has come to be known as the compact digital audio disc, or C-DAD.

If the companies meet their production target dates, Japanese and European music lovers should be able to purchase a new kind of disc player in late 1982, while U.S. audio enthusiasts will have to wait a bit longer-until the beginning of 1983. From all indications, the long wait will be worthwhile, for the new digital C-DAD disc (sometimes acronyms become part of the language long before the item they represent is available) offers a level of performance that has been impossible to obtain with conventional analog records, no matter how carefully they were recorded and processed.

One hour of stereophonic music per side

The new Philips-Sony C-DAD disc is capable of playing one hour of stereophonic music per side, and can also hold up to four channels of audio on a side with reduced playing time.

Laser beam

Information on the C-DAD disc consists of approximately six billion digital "bits" which are linearly encoded along a helical track of pits and flats.The tiny pits are about 0.6 microns in width and 0.2 microns deep. The pits and flats represent the "ones" and "zeros" in the digital code used to store the signals. A solid-state laser beam is used to sense the sequence of pits and flats using a spot of light with a diameter several times smaller than that of a human hair. The laser beam reads the presence or absence of the pits contained in the discs' surface beneath a protective plastic coating. The scanning rate is approximately 4.3 million bits-per-second.Variations in the reflected light rays are then converted into digital code and finally, through D/A conversion, back into a continuous audio waveform.

No physical contact

Since there is no physical contact between the pickup and the surface of the disc, the pickup must be guided by a dynamic-tracking servo system. The lack of physical contact also means that record wear is totally eliminated.

Great many possibilities designing C-DAD players

Unlike the turntables used to play today's analog records, the rotating platter that spins the C-DAD disc has a variable rotational speed - 200 rpm when the laser its at the circumference of the disc and around 500 rpm when it is 50 millimeters from the center, the inner radial limit. Scanning takes place from inside to outside and rotation is counterclockwise. The total storage capacity of the C-DAD disc is over 8 billion bits per side-far more than is necessary for the60 minutes of playing time that has been standardized for the disc. That provides a great many additional possibilities for designing C-DAD players. Both the Philips and Sony prototype players: that were shown last spring were able to "read out" such additional useful information as the number of the selection being heard, its length, the sequence of numbers programmed to be heard, etc. Owners of C-DAD disc players will be able to make use of sophisticated programming circuitry, enabling them to determine which songs they want to hear and in what sequence they want to hear them.

Digital performance

The frequency response of the system is absolutely flat from 20 Hz to20.000 Hz. The digital sampling frequency is 44.1 kHz, which would theoretically give a response up to 22.05kHz. Some margin, though, is left for high frequency cut-off filtering. The signal-to-noise ratio for the 16 - bit digitizing format is better than 90 dB (theoretically, it could be as high as 97.5 dB); dynamic range-the difference in level between softest and loudest sounds that can be handled-is also better than 90 dB. Channel separation is 90 dB as well, while total harmonic distortion, referred to peak levels, is 0.05% or less (0.03%, theoretical). As with any true digital-sound system there is no measurable rumble or wow-and-flutter. Tracking, decoding,and rotational speeds are synchronized by a central clock generator inside the player and the clock is itself governed by information encoded in the track on the disc.

Digital performance

Since the digital data representing the music is stored briefly in semiconductor memory in the player before being clocked out at a steady rate to the digital-to-analog converter, there can be no wow or flutter in the conventional sense. There is also no audible inter modulation-distortion of the type that plagues conventional analog recordings to such a large degree. To fully appreciate the significance of these performance levels, which compares the C-DAD system with conventional LP records.

Many digital-audio disc systems

Of the many digital-audio disc systems that have surfaced over the last several years, two besides the C-DAD system have been successfully demonstrated and been under consideration by a 51-member Digital-Audio Disc Council. That group deliberated about standardization for about three years (and has only recently been disbanded) in Japan. The two other systems are:

-

A capacitance-pickup system, developed by JVC as an adjunct to its VHD videodisc system which is to be marketed in early 1982 and which has been given the name AHD (Audio High Density).

-

A mechanical "groove-type" system developed by Telefunken.

AHD

Discs for the variable-capacitance system (AHD) are made of conductive materials. Digital signals in the form of tiny pits are engraved in these discs. As a miniature metal electrode follows the pits, signals, represented by changes in electrostatic capacitance, are detected. To maintain the necessary accuracy, the pits are en- graved on the surface of the disc along with pilot signals impressed on either side of the audio signal pits. Since there are no physical grooves impressed into its surface, the pilot signals are used as part of a dynamic-tracking servo system to keep the electrode stylus properly positioned along the signal track of the AHD audio disc.

Telefunken

In the mechanical system developed by Telefunken, playback is accomplished in a manner similar to that used by ordinary analog players. That is, signals cut into the grooves of the disc are first converted into mechanical vibrations as the stylus traces demand the vibrations are then transmitted through a pickup arm to a piezo electric converter, where they are changed into electrical signals.

Which system in the future?

Of the three, only the Sony-Philips and the JVC systems seem likely to reach the marketplace in the near future. JVC's argument in favor of its system is based largely upon the fact that a single player would be able to handle both its videodiscs (the VHD discs that are to be marketed in 1982)and the AHD digital-audio discs, since both use a capacitance-pickup principle. Of course, a digital-to-analog converter/processor would have to be added to the JVC system for decoding the digital-audio discs; the addition of such a D/A converter/processor would make the lower cost argument somewhat questionable.

The JVC AHD disc, like its companion VHD disc, is a little over 10inches in diameter and comes supplied in a "caddy" or holder that protects the disc surface when it is not being played.The smaller, optically-tracked, C-DAD disc requires no such protective sleeve,of course, and is in no way affected by dirt or dust on its surface since the focal point of the laser beam is beneath the transparent surface of the disc. An important point that has been emphasized many times by Sony and Philips is that the small C-DAD disc and its correspondingly small player can easily be adapted for use in cars and other moving vehicles, since the vibration of a vehicle should have little or no effect upon laser tracking.

Disc production

There seems to be a growing trend towards endorsement of the C-DAD system by equipment manufacturers and "software" (recorded material) producers around the world. Matsushita Electric Company (whose line of brands includes Panasonic. Quasar, Technics and National), although committed to the JVC VHD system for videodiscs, has nevertheless indicated that it will produce disc players for the Sony-Philips system. Recently, the worldwide Polygram Group, one of the leading international record manufacturers, and CBS/Sony, Inc., the largest record company in Japan, announced plans to produce music programs in the C-DAD format. In 1982, for example,CBS/Sony will release more than 100 C-DAD albums in Japan simultaneously with the introduction of the C-DAD players. On the hardware side, companies such as Marantz have already demonstrated their own versions of players which are compatible with the Sony -Philips optical -laser disc system.And, while the 51 -member Digital Audio Council mentioned earlier did not specifically endorse the C-DAD system, its final report noted its compact size and its applicability to mobile use, which many interpreted as being just about as close to an endorsement as such a committee would ever be likely to come.

Disc prices

Once you get past the hurdle of paying for a C-DAD optical-laser player (about the price of a high-end turntable), the software or discs themselves should be no more expensive, on a "per-minute-of-music" basis, than high-quality LP records. The process of making digital discs is quite different from the process currently used to make analog LP records, but once it has been mastered, it should be possible to turn out the new discs on a mass-production basis that will reduce disc prices drastically.

Disc production

Mechanical cutting-techniques are impractical for digital-disc production because the pits to be carved are far too small. Instead, first, a glass plate coated with photo-resist material is exposed to a digitally-modulated laser beam. The plate is then developed to form pits corresponding to the presence or absence of digital signals. After a silvering process, that glass plate becomes the"master."

It is next pressed against a nickle plate to make an inverse copy (the pits become small bumps and the flats become depressions) of the photo-etched depressions on that plate. A digital-master is thus produced which, in turn,is used as the "mother" for making production "stampers." Each stage inverts the surface of the disc (pits-bumps-pits-bumps, etc.). The stampers have bumps.

The final production stages

Using the stamper, C-DAD discs are produced in large quantities in much the same manner as conventional analog records. The signal-bearing surface of each disc is then coated with a reflective material, followed by a coating of protective, transparent plastic. Aside from any labeling and packaging that may be required,that completes the manufacture of a single-sided disc.

For a two-sided disc, an additional process to combine two single-sided discs would be required, but it is entirely possible to produce such two sided discs.

Advantages of digital recording

Recognizing the advantages of digital recording almost as soon as it was made available on a commercial basis to recording studios several years ago,many recording companies around the world have been producing digital-master-tapes for release as digitally-mastered, improved analog LP's (often erroneously referred to as "digital" records). Although many of those recordings have been praised as being clearly superior in sound quality to conventional LP's, they obviously cannot approach the performance levels that will be reached by C-DAD discs once they are made available.

Digital source-material

The fact that so many digital master tapes now exist in the archives of major recording studios bodes well for the future of true digital-discs. All those tapes can be used to make true digital-audio discs, with no degradation in quality from master tape to disc. The Sony-Philips system, in fact, uses the same 16-bit PCM (Pulse Code Modulation) encoding currently being used for professional digital-audio purposes. Therefore, C-DAD recordings can be made in studios using existing PCM equipment. It is also possible to translate existing analog recordings, using PCM processors, to the C-DAD format. However, should that be done, the resulting product would not exhibit the increased dynamic range and other improvements made possible by digital-recording technology.